Conductive

Welcome to Conductive

Welcome to Conductive. Conductive is here to provide a more dynamic presentation of company news, events, industry developments and articles of interest. Content will be added regularly, you'll want to add this to your bookmarks and check back often.

The Battery Show 2016 Presentation

Sep 15 2016Bob presented to a large audience yesterday at The Battery Show 2016. He was part of a panel of presenters that spoke on Refining and Improving Lead-acid Technologies. His presentation was on applications of Bi-polar Plate Technology to New Opportunities in the EV/HEV Automotive Market. Other speakers on the panel with Bob were, Scott McCaskey - East Penn Corp., Maureen Murphy – Hammond Group and Yunfeng Lu PhD – UCLA.

Lightweighting remains top focus for automakers to meet CAFE standards

Aug 9 2016Drive train efficiency also high on the agenda; aluminum, multi-material solutions viewed as key enablers

By Stephen Moore in Automotive and Mobility, Materials, Sustainability on August 03, 2016

By Stephen Moore in Automotive and Mobility, Materials, Sustainability on August 03, 2016

Taking weight out of vehicles and engine efficiency programs continue to top the list of strategies for automakers as the industry looks for ways to meet 2025 CAFE (Corporate Average Fuel Economy) standards. The recent findings were part of the annual WardsAuto survey, sponsored by DuPont Automotive.The survey also showed electrification as an increasingly mentioned technology focus by the respondents. In fact other studies, such as one reported by Lux Research earlier this year, highlights micro-hybrid technologies as contributing 48% of the improvements required to meet 2025 target versus 39% for lightweighting. Reducing friction in drive trains has also be identified as a potentially more efficient means of reducing fuel consumption versus lightweighting. In any case the good news for plastics molders is that all of the above solutions involve use of plastics.

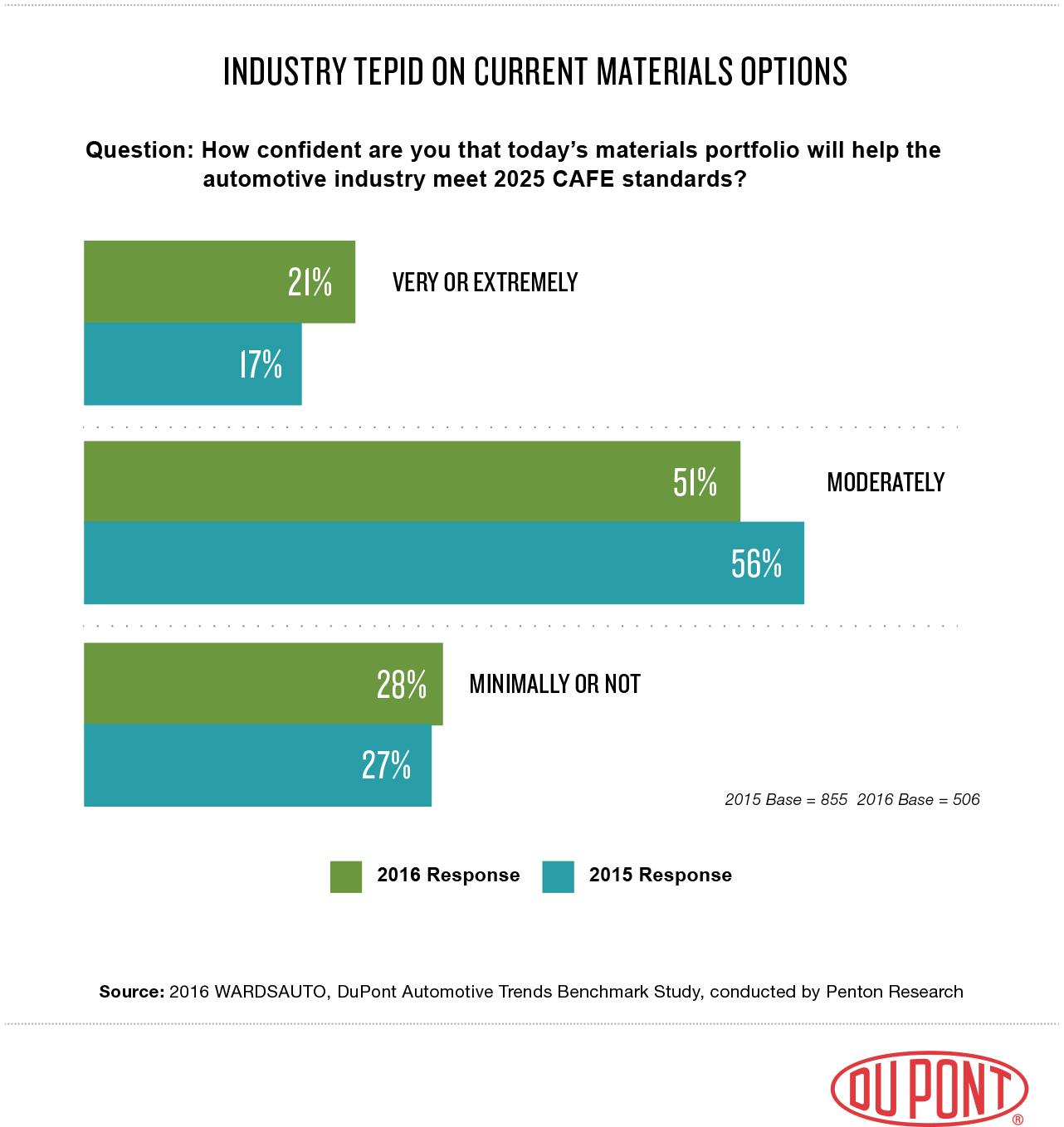

The auto industry feels current material choices may be insufficient in meeting 2025 CAFE requirements.

The recent fuel efficiency scandal at Mitsubishi Motors has thrown the spotlight on whether the 54 mpg+ target mandated by CAFE is realistically achievable or not as highlighted by a recent article by Plastics Today’s Clare Goldsberry. The light-duty vehicle CAFE and GHG (greenhouse gas) emissions rate standards require, on an average industry fleetwide basis, 163 g/mile of CO 2 in model year 2025, which would be equivalent to 54.5 mpg (4.3 L/100 km) if this level were achieved solely through improvements in fuel efficiency. Moreover, a mid-term review scheduled for 2017 may make these standards even more stringent.

However, 54.5 mpg is a non-adjusted theoretical laboratory compliance value that does not include special credits for such things as high-efficiency air-conditioning systems and active grille shutters that improve vehicle aerodynamics. Most experts believe 54.5 mpg will translate to about 40 mpg in real-world fuel economy.

“It’s no surprise to learn that lightweighting and the use of lightweighting structural materials continue to top the list of strategies the industry remains focused on,” said Brian Fish, NA automotive marketing manager, DuPont Performance Materials. “Lightweighting can be applied to virtually every component and part and we continue to work with the industry to look for opportunities to reduce weight across systems.”

With the mid-term review of the 2025 CAFE Standards scheduled through 2017, 52 percent of the respondents say they expect the standards for fuel economy and emissions to become more stringent, while 35% expect them or remain the same. At the same time, 90 percent say low gas prices in combination with slow sales of fuel efficient, low-emissions vehicles will continue to impact programs aimed at meeting CAFE regulations.

Now in its sixth year, the DuPont-sponsored survey with WardsAuto was conducted by Penton Market Research (Overland Park, KS). The 600-plus respondents work for system, component or parts manufacturers, automakers, engine or engine-service companies or in automotive-related industries. Most represent engineering, design, manufacturing, marketing, sales and corporate management.

Among the questions in the survey, respondents were asked to identify technologies that their companies are focusing on to help meet the 2025 standards. A majority of respondents (63 percent) are focused on lightweighting and the use of lightweight structural materials and nearly half (49 percent) are focused on engine efficiency programs.

While lightweighting was at the top of the technology focus area, powertrain and chassis continue to remain as the top two vehicle systems that automakers target for lightweighting. Of the respondents, 44 percent mentioned powertrain and chassis as the primary areas for lightweighting.

Respondents continue to be only moderately confident that the current portfolio of materials will help the industry meet the looming standards. “Investing in the development of innovative and high-performance materials is a key strategy for DuPont,” said Brian Fish. “We continue to actively partner with the automotive design and engineering community to find new solutions to reduce vehicle weight.”

According to the survey respondents, the most relied upon material families to help meet the CAFE standards are aluminum (25 percent) and multi-material solutions (21 percent). Advanced composites, engineered plastics and advanced high-strength steel were the top second tier choices with all three materials combining for 39 percent of the respondent’s choices.

High Volume Manufacturing

Jul 27 2016The above video shows our first production run utilizing this high volume process. We are continuing to improve our manufacturing capabilities.

Saltwater Testing

Jul 1 2016Successful completion of a 90 day trial of ElectriPlast submerged in saltwater with a continuous electric current applied. This test is required for a customer with an underwater ocean application.

Advanced Battery Concepts

Jun 6 2016Mo Zeidan and Bob Pavlovic were at Advanced Battery Concepts for a successful week of ElectriPlast Bi-polar battery plate manufacturing.

Plate Production ABC Facility Testing

Safe Harbor Statement

These post may contain "forward-looking statements'' within the meaning of Section 27A of the 1933 Securities Act and Section 21E of the 1934 Securities Exchange Act. These statements include, without limitation, predictions and guidance relating to the company's future financial performance and the research, development and commercialization of its technologies. In some cases, you can identify forward-looking statements by terminology such as, "may," "should," "expects," "plans," "anticipates," "believes," "estimates," "predicts," "potential," "continue," or the negative of these terms or other comparable terminology. These forward-looking statements are based on management's current expectations, but they involve a number of risks and uncertainties. Actual results and the timing of events could differ materially from those anticipated in the forward-looking statements, as the result of such factors, risks and uncertainties as (1) competition in the markets for the products and services sold by the company, (2) the ability of the company to execute its plans, (3) other factors detailed in the company's public filings with the SEC, including, without limitation, those described in the Company's annual report on Form 10-K for the year ended June 30, 2017 as filed with the Securities and Exchange Commission and available at www.sec.gov, and (4) the parties may be unable to agree upon definitive agreements. You are urged to consider these factors carefully in evaluating the forward-looking statements.